Hard Candy Production Machine

Specifications

The sandwich milk candy (hard candy) production line is a multi-functional candy production line independently developed and produced by us. The candy has good molding effect, no bubbles and high productivity

- PLC adopts international famous brand, with more stable performance. It automatically controls the temperature, time, insulation temperature and pouring speed of vacuum sugar boiling by programming. The 10.7 inch LED touch screen display is easier to operate

- The production capacity of the series of products can range from 150 kg to 1200 kg per hour

- Variable frequency speed regulation controls the flow of sugar liquid, and the dynamic mixer completes the quantitative filling and mixing of essence, pigment and acid liquid online

- Conveying chain belt, cooling system and double demoulding mechanism ensure that different shapes of candy can be produced according to different molds

- Replace some devices and molds, and the production line can produce spherical and flat three-dimensional lollipops

Application:

Milk candy, hard candy, vitamin hard candy, vitamin sandwich hard candy, toffee, crisp candy

PROFILES:

- HARD CANDY DEPOSITING LINE adopt four taper-shaped rollers to run in the same speed and direction,make the confection even,and keep the jam in the center of candy constantly.

- Adopt several pulling wheel group to make the candy strip even,and convenient for forming.

- Adopt the forming theory of acentric mould core type,make the forming result perfectly.

- Adopt refrigeration technique, cool the formed candy swiftly for packing.

MAIN TECHNICAL PARAMETERS:

| Model | ME-TB1 | ME-TB2 |

| capacity | 200-400kg/h | 400-600kg/h |

| power | 19kw | 20.5kw |

| Machine size | 8250*1200*1400mm | 8600*1200*1700mm |

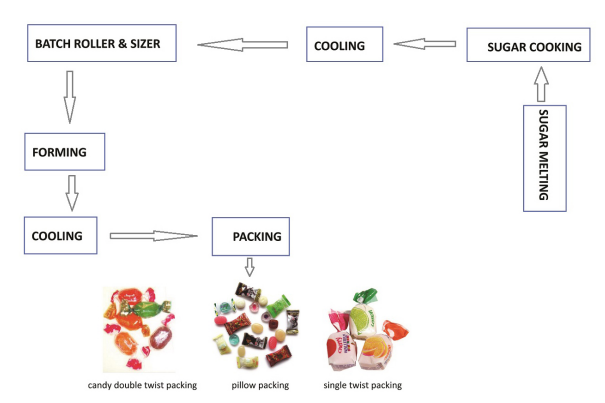

Production Process

1.Sugar pot:steam gas sugar cooking machine food vacuum cooker for candy machine

Characteristics:

1)It can bear 3-4 kg pressure. It has pressure vessel license.

2) It has mixing function to prevent sugar from be burnt.

3) It is an interlayer pot. It is hearted uniformly, the up and down temperature are the same. The pressure and temperature can be controlled.

4) The pot body which contacts the sugar is made of stainless steel 304.

Application

It has stirrer, reducer and motor with temp. meter and pressure meter.

Main technical:

| Voltage | 380V, 3phases, 50Hz |

| Maximum capacity | 300L |

| Mixing power | 1.5 kw |

| Mixing speed | 30 rpm |

| Pot inner diameter | 900 mm |

| Steam pressure | 0.4 MPa |

| Weight | 200 kg |

| Dimension | Φ1000×1200 mm |

2.Sugar storage tank

3.Sugar cooker

Vacuum Continuous Sugar Pan

The vacuum sugar pot is a sugar-making equipment with steam heating, condensation, vacuum tank and other processes. This machine has the advantages of simple operation,reasonable structure, stable performance, convenient adjustment and maintenance, and long service life

Specification:

Maximum yield: 400kg/h

Heating area: 2.45m2

Steam use pressure:0.59Mpa5.5-6Kilograms per square centimeter

Steam consumption when maximum production: 110kg/h

Boundary dimension:105-115℃

Glycocalyx temperature after heating:135-145℃

4.Cooling table

Application: use water for cooling

Dimension:2200*1200*800mm

Material: Stainless steel 304

5.Batch roller

The batch roller main used four prick roller circum gyrate in the same time so that extrude and press sugar from thick to thin.

It’s the main equipment that making hard candy, cream candy and lollipop. The machine is characterized with unique features such as reasonable structure, superior performance, and pleasant appearance, easier operation and maintenance and is designed for the convenience of your production.

6.Rope sizer

Full automatic hard candy making machine rope sizer

This machine adopts five pulling wheel whose specification is different to push and press the rough cone-shaped sugar into cylindral sugar strip. This machine is the main equipment to produce hard candy and milk candy and has the advantages of reasonable structure, easier operation, and high pressure capacity and so on.

7.Forming machine

The output of this hard candy forming machine is 1-3T per shift, and the speed can be adjusted at will. It can produce hard candy and milk candy of various shapes. The exquisite design is reasonable, and the operation is simple. It is the choice for candy molding. We can choose molding machines with different output according to the customer’s needs

8.Cooling tunnel

COOLING TUNNEL mainly used to cooling lollipop, hard candy and soft candy, this machine has advantages of reasonable structure, easier operation, and high eligibility rate. It’s the main equipment for kinds of candy, the compressor can ensure the final products with good effective.