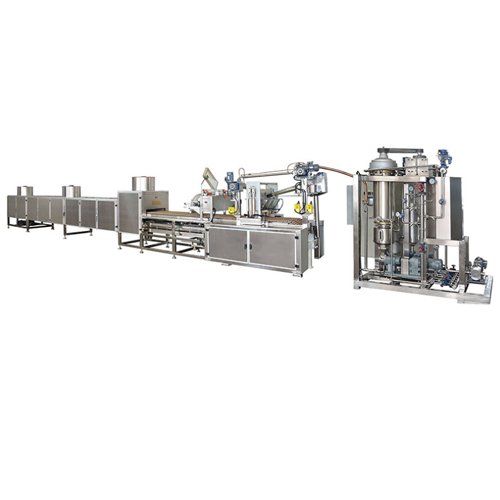

Candy Machine Production Line

- Jelly candy depositing line candy making machine

- Lollipop depositing machine

- Lollipop die-forming candy machine

- Toffee candy depositing machine

- Hard candy former machine

- Servo motor gummy jelly candy making machine

- Soft candy production line

- Gummy candy machinery

Specialized Candy Machine Production Line Supplier

Melesun specialized in the production of biscuit machinery, baking equipment, candy machinery, pastry machinery. Our complete set of biscuit equipment, cookies and pastry machines, baking equipment, and candy machinery are in various food factories at home and abroad. Our candy machine integrates mechanical, electrical and pneumatic control, with reasonable and compact structure, high automation degree and production efficiency. It can produce hard candy, lollipop, sandwich candy, gelatin soft candy, pectin soft candy, carrageenan soft candy. Monochrome, two-flavor, two-color spray, two-flavor, two-color, two-color spray, three-flavor, three-color spray, crystal candy, sandwich candy, article candy, etc

Candy production line is a kind of equipment for continuous production of different kinds of colloidal soft candy. It can produce a variety of shapes, monochrome, multi-color and sandwich gel fudge by changing the mold or pouring head. The whole production line consists of sandwich sugar pot, mixing and storage pot, pouring machine, refrigerator, conveyor, roller sander (optional), polishing machine (optional). It can be used in the production of various gel raw materials, such as gelatin, pectin, carrageenan and arabic gum. Automated production can not only save manpower and space, but also reduce production costs. Electric heating system is optional.

Technological process:

Soft candy: melting sugar → cooling → pouring molding → cooling → demoulding → wrapping granulated sugar/sugar powder → drying → packaging

Hard candy: melting sugar → vacuum boiling sugar → pouring molding → cooling → demoulding → packaging

Lollipop: sugar melting → vacuum boiling → pouring molding → stick insertion → cooling → demoulding → packaging

We provide perfect design, planning and construction, and constantly innovate to meet customers’ requirements with reasonable price and excellent quality. Over the years, in line with the strong technical force, we have continuously improved the process, improved the quality, developed new products, and provided users with satisfactory and reliable equipment.

The deposited lollipop production line is one kind of art candy production equipment which suits for the large grain of candy shape. This machine not only producing semi-solid and full solid lollipop but also producing normal lollipop. such as single colour, double colour double flavour lollipop, stripe lollipop. This machine with a mechanic. electric, pneumatic and cancel the cam system, construction tightly, designing reasonable.with high automation, it is a perfect lollipop production equipment.

Hard candy depositing plant consists of auto-weighing dissolving system, microfilm cooker or microfilm rotary cooker, servo depositing machine with cooling tunnel and sticker insertion system. The machine with motion controller system makes production with high automation, high output, better appearance of lollipops, suit for producing single colour lollipop, double colour double flavour lollipop, twin ball lollipop, stripe lollipop and so on. This machine is more efficiency and easy operation.

This machine is with many advantages of compact structure, reliable performance and high level of automation, consists of the batch roller, rope sizer. forming machine. cooling tunnel & wrapping machine.etc.The pressing – style mould can ensure plump shape for the lollipop and reliable sticker inserting. With waggling cooling conveyor, there is less distortion resulting in perfect lollipop surface, the production line can produce soft candy, hard candy, spherical lollipop, flat lollipop and so on.

It is with PLC, the performance is more stable, and the programming automatically controls the vacuum sugar boiling temperature, time, holding temperature and pouring speed, the production capacity of series products can range from 150 kg to 600 kg per hour; The accurate flow of sugar liquid is controlled by frequency conversion and speed regulation, and the quality of sugar paste is stable; The dynamic mixer completes the quantitative filling and mixing of essence, pigment and acid liquid online.

Hard sugar vacuum film boiling equipment Sugar boiling machine is composed of syrup quantitative pump, preheater, vacuum film evaporator, water ring vacuum pump, discharge pump, temperature and pressure measuring instruments and electrical control box. All components are installed on the same frame and connected with various pipe valves. Hard sugar boiling equipment Vacuum film boiling equipment Sugar boiling machine unit has the characteristics of high yield, high sugar boiling quality.

Why Choose Melesun Package

We have strong manufacturing capacity, we can make samples in short time, and delivery products quickly if you need the products urgently. Especially when you are short of stock or seasonal promotion, it is very important.

We are experienced and specialized in these packages, so you just contact us for all these packagings, we can provide you quality and competitive products, it save your time of looking for different suppliers.

All of our packages are environmental and suitable for food packing, we have full range of certificates and also we can test for you according to your requirements, so you can be reassured from purchasing to selling.

We can store your products and ship all of these products together by one time as soon as they are finished, the container space can be used as most as possible, it save your warehouse cost, shipping cost and energy.